The Role of AI in Designing Self-Optimizing Supply Chains

The Role of AI in Designing Self-Optimizing Supply Chains

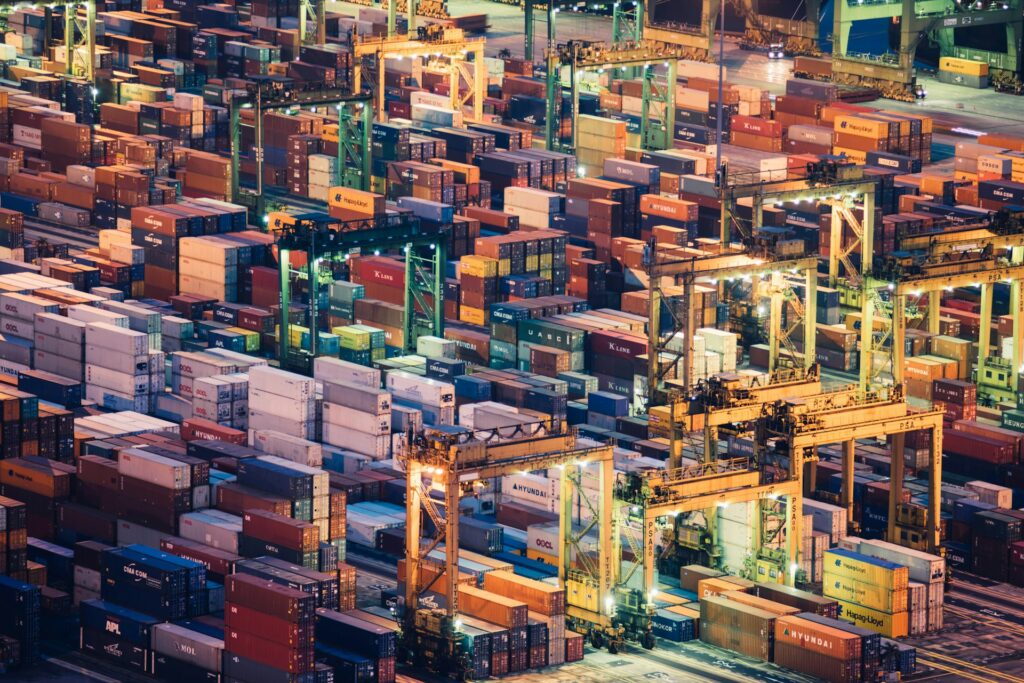

Supply chains in the modern era are intricate, linked systems that are required to react rapidly to fluctuating demand, interruptions, and global uncertainty. Supply chain models that are considered traditional depend mainly on static planning and human modifications, both of which often fail to keep up with the unpredictability that exists in the actual world. The use of artificial intelligence is causing this environment to undergo a transformation by making it possible for supply chains to continually assess, learn, and enhance their efficiencies. Artificial intelligence is used in self-optimizing supply chains to make dynamic adjustments to processes without requiring continual involvement from humans. The advancement of this technology enables firms to continue to retain their efficiency, resilience, and reactivity in circumstances that are unexpected.

Maintaining a Constant Integration of Data Throughout the Supply Network

The continuous flow of data from suppliers, manufacturers, warehouses, transportation systems, and market signals is essential to the operation of supply chains that are driven by artificial intelligence. A unified image of the whole network is created by AI systems via the integration of this data. The supply chain is transformed into a linked intelligence system, which eliminates the need for individual components to function independently of one another. The ability to recognize disruptions and developing trends more quickly is made possible by real-time data. Self-optimization is built on this integrated visibility, which serves as its basis.

Forecasting and Planning of Demand in a Dynamic Approach

When it comes to supply chain efficiency, accurate demand forecasting is absolutely necessary. In order to provide more accurate forecasts of demand, artificial intelligence algorithms examine previous sales data, seasonal trends, consumer behavior, and external influences. As opposed to more conventional techniques of forecasting, artificial intelligence continually changes its forecasts whenever fresh data is made available. It is possible for supply chains to make adjustments to production and inventory levels in real time thanks to this dynamic planning. Organizations are able to decrease overstocking, shortages, and lost sales opportunities as a consequence of this reduction.

Utilization of Intelligent Inventory Management

In order to establish the appropriate inventory levels across various sites, self-optimizing supply chains make use of artificial intelligence. A number of elements, including demand fluctuation, lead times, storage costs, and service levels, are taken into consideration by AI systems. Adjustments to inventory choices are made automatically if circumstances undergo a change. This results in less carrying costs while also preserving product availability. Improvements in cash flow and operational efficiency may be achieved by enterprises via the intelligent optimization of inventory.

Adaptable Administration of Transportation and Logistics

A significant portion of the supply chain that is both difficult to understand and expensive to operate is transportation. Using artificial intelligence, routes, carrier performance, fuel costs, and real-time traffic or weather conditions are all analyzed. These insights are used to make dynamic adjustments to logistics plans in order to reduce the amount of time and money wasted on delays. The ability to rapidly redirect shipments in reaction to interruptions is a capability of AI-driven systems. Because of this versatility, timely delivery are guaranteed even in circumstances that are turbulent.

Detection and mitigation of risks in a proactive manner

The supply chain is vulnerable to a broad variety of hazards, such as the failure of suppliers, the occurrence of geopolitical events, and the interruption of natural processes. Continuous monitoring of risk indicators throughout the network is performed by AI algorithms. It is possible for businesses to activate their contingency plans when potential problems are discovered at an early stage. Supply chains that are capable of self-optimization do not wait for interruptions to occur; rather, they engage in proactive preparation for them. The robustness and continuity of operations are considerably improved by this capacity.

Execution and Decision-Making That Are Fully Automated

One of the most important aspects of supply chains that are capable of optimizing themselves is the capacity to make and carry out choices autonomously. Artificial intelligence systems analyze a number of different situations and choose the most effective course of action. In the areas of procurement, manufacturing, and distribution, these choices are executed without any delays caused by human intervention. By automating processes, human error may be reduced, and reaction times can be enhanced. Human teams continue to concentrate on strategy rather than making continuous improvements to operational procedures.

Acquiring Knowledge and Making Constant Improvements Over Time

Artificial intelligence-driven supply chains are always learning to improve. Every choice and result is sent back into the system, which enhances the decisions that will be made in the future. Over the course of time, the supply chain will progress toward more precision, efficiency, and resilience. Through the use of this learning loop, firms are able to adjust to the ever-changing market circumstances and the demands of their customers. Instead of being a one-time enhancement, self-optimization evolves into a competence that can be maintained over time.

Long-Term Effects on the Supply Chain Operation Strategy

The incorporation of artificial intelligence into the architecture of supply chains is causing a shift in the way that businesses think about logistics and operations. Supply chains that are capable of optimizing themselves move the emphasis away from human control and toward intelligent orchestration. Increased customer happiness, decreased expenses, and increased agility are all benefits that accrue to businesses. As artificial intelligence capabilities continue to grow, self-optimizing supply chains will become the norm for firms that are competitive and prepared for the future.